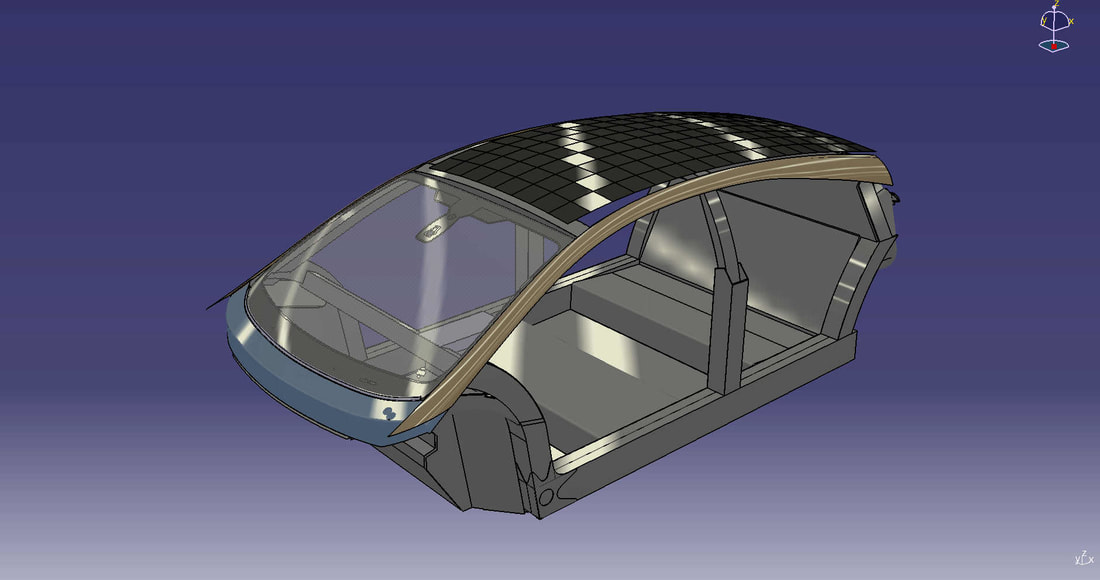

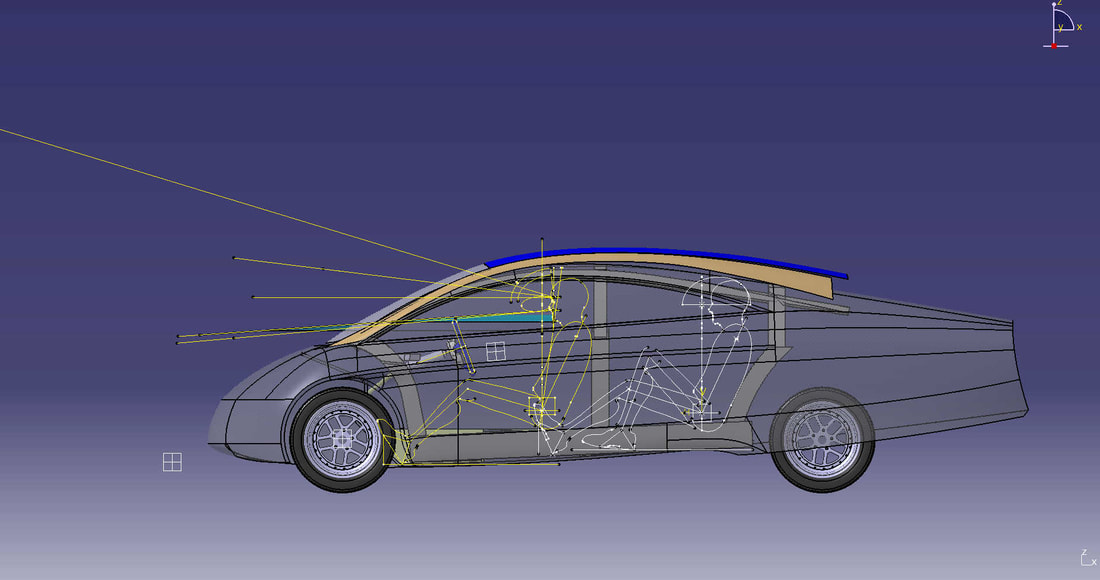

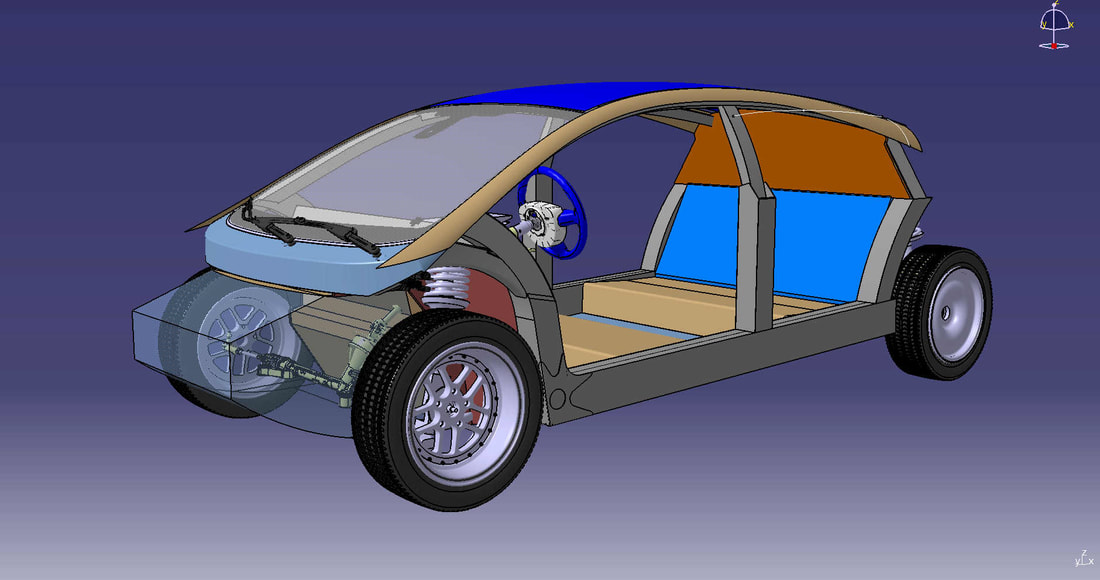

Chassis Design

Our chassis team has nearly a century of experience in both road and racecar chassis development some members have been involved in the design of some of the most iconic and notable automobiles of all time. We take much pride in the level of achievement our team has amassed, and its skillsets provide Velfera with the talent needed to design and build some of the lightest and strongest chassis on the market today.

We employ several technologies in the development of modern lightweight chassis structures based on the application requirements. Reducing a vehicle's weight is key to improving efficiency, on-road performance, braking and handling. Strategies employed included the use of:

- Folded Honeycomb Structures

- Molded Carbon Fiber Tub with Aluminum or Carbon Fiber Sub-frames

- Extruded Aluminum Frames with Honeycomb Floors and Bulkheads

- Extruded Aluminum Frames with Cast Aluminum Joining Nodes

We use any combination of these to create structures that are light, strong and offer good torsional rigidity all while enhancing occupant safety. Our team is currently working to scale-up these techniques to enable annual vehicle production runs of up to 25,000 units.

Key differentiators for our Honeycomb Chassis Architecture:

- No Jigs or Fixtures required to assemble

- No Expensive Metal Stamping Tools or Dies

- No Welding or Riveting, Fully Bonded Structure

- Easy to Assembly by Hand, or Robotic Arm

- Flat Packable for shipment Globally for Final Assembly

- Design changes in CAD can be implemented immediately with a simple software

file update to the production equipment

- Highly dimensionally accurate milling process guarantees production repeatability

This chassis is a completely self-jigging milled part, which in a controlled process, can be assembled by 2 technicians in 30 min, thus eliminating the cost and complexity of the chassis assembly process. Through tight control of the material sourcing we believe that this technology will be cost competitive for low to medium volume production runs. Additionally, this technology scales from automotive to large commercial vehicle applications.

Our chassis team has nearly a century of experience in both road and racecar chassis development some members have been involved in the design of some of the most iconic and notable automobiles of all time. We take much pride in the level of achievement our team has amassed, and its skillsets provide Velfera with the talent needed to design and build some of the lightest and strongest chassis on the market today.

We employ several technologies in the development of modern lightweight chassis structures based on the application requirements. Reducing a vehicle's weight is key to improving efficiency, on-road performance, braking and handling. Strategies employed included the use of:

- Folded Honeycomb Structures

- Molded Carbon Fiber Tub with Aluminum or Carbon Fiber Sub-frames

- Extruded Aluminum Frames with Honeycomb Floors and Bulkheads

- Extruded Aluminum Frames with Cast Aluminum Joining Nodes

We use any combination of these to create structures that are light, strong and offer good torsional rigidity all while enhancing occupant safety. Our team is currently working to scale-up these techniques to enable annual vehicle production runs of up to 25,000 units.

Key differentiators for our Honeycomb Chassis Architecture:

- No Jigs or Fixtures required to assemble

- No Expensive Metal Stamping Tools or Dies

- No Welding or Riveting, Fully Bonded Structure

- Easy to Assembly by Hand, or Robotic Arm

- Flat Packable for shipment Globally for Final Assembly

- Design changes in CAD can be implemented immediately with a simple software

file update to the production equipment

- Highly dimensionally accurate milling process guarantees production repeatability

This chassis is a completely self-jigging milled part, which in a controlled process, can be assembled by 2 technicians in 30 min, thus eliminating the cost and complexity of the chassis assembly process. Through tight control of the material sourcing we believe that this technology will be cost competitive for low to medium volume production runs. Additionally, this technology scales from automotive to large commercial vehicle applications.